Demystifying Excavator Hitch Sizes: Choosing the Right Fit for Optimal Performance

Share

Excavators are powerful machines capable of performing a wide range of tasks in construction, demolition, and excavation projects. One crucial aspect that greatly impacts their versatility is the excavator hitch size. In this blog, we'll explore the significance of choosing the right hitch size, how it influences equipment compatibility, and why selecting the appropriate hitch is vital for achieving optimal performance on the job.

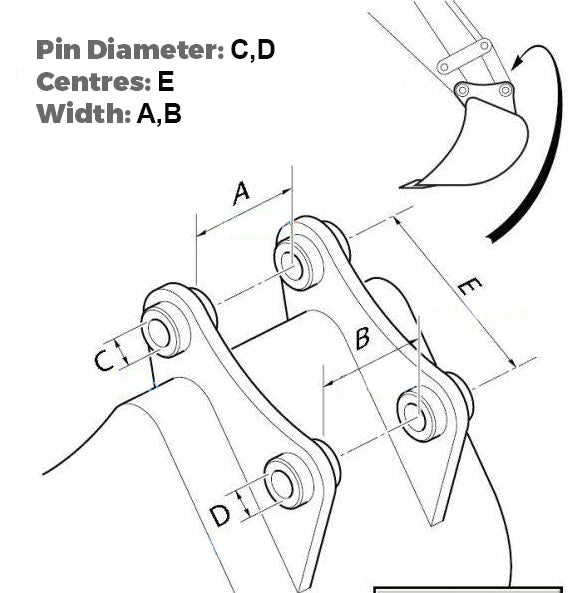

1. Understanding Excavator Hitch Sizes:

Excavator hitches are the essential connectors that attach various attachments to the machine's arm. They come in different sizes, known as or categories, which are standardised to match specific excavator models.

2. The Importance of Proper Fit:

Selecting the correct hitch size is critical for seamless attachment compatibility. An ill-fitting hitch may result in safety hazards, reduced performance, and potential damage to the equipment. Proper fit ensures smooth and efficient operation during diverse tasks.

3. Hitch Classes Explained:

Excavator hitch classes are categorized based on pin sizes and dimensions. The most common classes include Labadi Engineering, CAT, JCB, Komatsu, and Volvo hitches. Each class corresponds to specific excavator models, facilitating easy matching of attachments to the appropriate machines.

4. Flexibility in Attachments:

By choosing an excavator hitch that suits various attachments, operators can quickly switch between tools like buckets, grapples, breakers, and thumbs. This adaptability enhances productivity, allowing for seamless transitions during different project stages.

5. Safety Considerations:

A properly matched hitch ensures the secure attachment of tools to the excavator arm. This reduces the risk of detachment accidents and guarantees a safe working environment for operators and those nearby.

6. Optimizing Equipment Performance:

Using the right hitch size optimizes the machine's performance and fuel efficiency. When attachments are well-suited to the excavator, less energy is wasted, resulting in cost savings and increased productivity.

7. Enhancing Project Efficiency:

Quickly swapping compatible attachments with a well-fitted hitch streamlines project workflows. This efficiency boosts productivity and reduces downtime, ultimately contributing to completing projects on time and within budget.

8. Professional Consultation:

When selecting an excavator hitch, seeking advice from qualified experts and manufacturers is highly recommended. They can provide valuable insights into the right hitch size for specific excavator models and project requirements.

Excavator hitch sizes play a crucial role in the versatility and performance of these powerful machines. By understanding the significance of choosing the right hitch class and ensuring proper fit, operators can enhance safety, efficiency, and productivity on construction sites. Whether it's a Labadi Engineering, CAT, JCB, Komatsu, or Volvo hitch, matching the correct size ensures seamless attachment compatibility and empowers excavators to tackle diverse tasks with ease, making them indispensable assets in construction and excavation endeavors.